FuelVu

Turn-Key Fuel Facility Maintenance, Repair, Upgrade and Construction

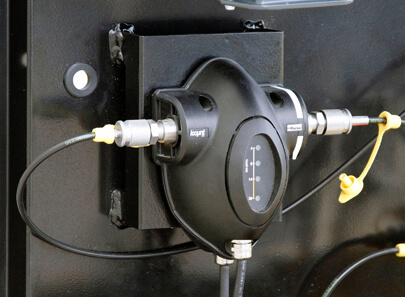

FuelVu Polishing – Integrates Laser Analyzer

FuelVu polishing technology integrates fuel analysis detecting particulates, bio-contamination & water levels in real time. Live monitoring confirms actual fuel polishing efficacy from data reported in ISO 4006 code format. This vital information provides operations key insight to diesel fuel condition, avoiding potential standby power failure.

- Tests size & number of particulates present per mL. Live data & alarms displayed via, PLC or facility dashboard

- Delivered bulk fuel fails to meet both ISO4006 cleanliness standards and mandates for cleanliness mandates for today’s generator specifications and warranty claims

- Adjust number of preset automated polishing cycles proactively averting quick fuel deterioration

- Extend fuel inventory life for UST, AST and sub-base tanks • Modular system architecture has small footprint is flexible, configurable and upgradeable

- FuelVu is cost comparative to current conventional units making the customer decision smart and easy!

Today’s low sulfur diesel quickly deteriorates promoting water, corrosion and algae growth shortening equipment life. Uptime failure is not an option, revenue, data, productivity, even human life depend on fuel system reliability.

Particle Counter & Moisture Analyzer