FuelVu - Operating Controls

FuelVu’s new generation of advanced technology was designed for the most critical applications, such as data centers, hospitals, telecom and other applications where redundant component dependability is essential.

FuelVu advanced fuel polishing system:

• Multi-stage, progressive particulate filtration & water removal

• Integrated, high-performance pump

• Monitoring devices and alarms

• Digital, user-programmable controller

FuelVu uses a progressive filtration & conditioning regime:

1. Coarse straining through 40 mesh washable screens

2. Final filtration through 5 micron disposable media filter

3. Water coalescing to 15 PPM

4. Water separation and collection

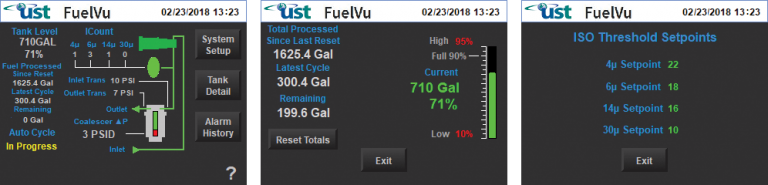

FuelVu controller screen examples:

Fuel circulation and transfer is accomplished via an on-board, high-performance, cast-aluminum, positive- displacement gear pump direct-driven via an industrial, heavy-duty motor. The pump combines high vacuum prime maintenance with linear flow versus pressure performance. An integral pressure relief valve is included. Drive motors are NEMA class industrial type, conservatively applied and include ball-bearings, class H insulation and continuous duty ratings.

The FuelVu system includes shutoff ball valves, check valves, pressure and differential pressure gauges, including differential pressure sensors across the filtration element.

Intelligent automation and operator interface is the hallmark of FuelVu. Each FuelVu is packaged with a digital controller. This UL508A listed and labeled industrial control panel features PLC-based digital control and touch-panel operator interface.

The controller provides full automatic operation of the system and is operator field programmable to set filtration cycle duration, time of day, day of week operation. Manual override capability is included. The controller monitors differential pressure across the filtration element and water level in the separator collection vessel.

Operational alarms are likewise generated. The controller is MODBUS or Ethernet network compatible for integration with remote Building Automation Systems or generator control switchgear.